About

ELECTRA demonstrates that electric heating can substitute fossil fuels in the cement, lime, and pulp industries.

ELECTRA develops and validates in real life emission-free, electrically heated cement, lime and lime mud production process in MW scale capable of reaching temperature up to 2000°C. By using low-emission electricity instead of combustion for decomposing calcium carbonate, and by capturing the carbon dioxide produced in the production process, it is possible to run plants with close to zero carbon dioxide emissions providing even negative-emission products for the society. Successful implementation of the ELECTRA concept will eliminate fuel-related CO2 emissions, and in addition, unavoidable calcination-related CO2 is captured efficiently and at low costs, resulting in over 90% total CO2 reduction and even enabling negative CO2 emissions across the targeted industries.

hub

17

partners

pin_drop

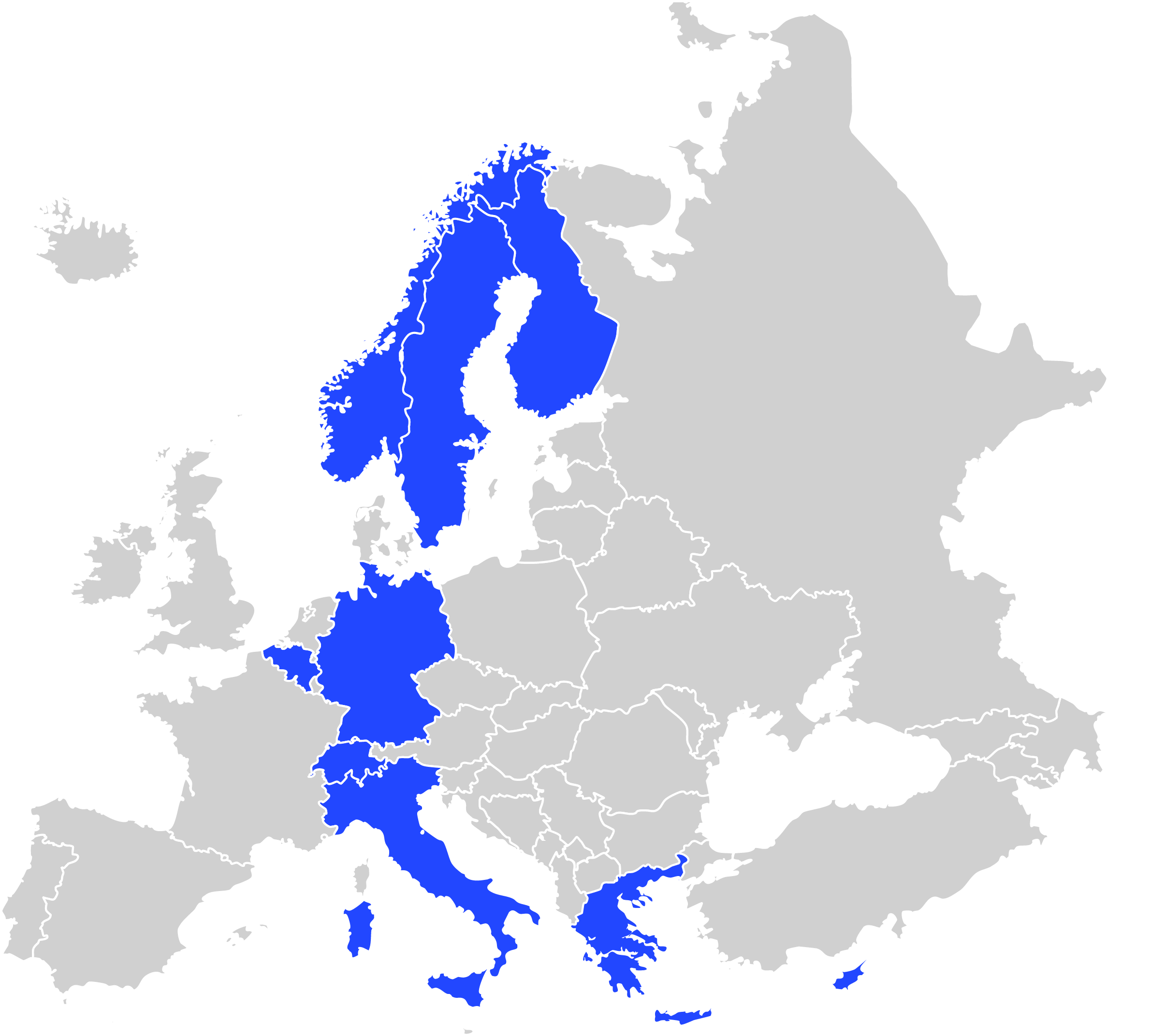

8

countries

date_range

48

months

euro_symbol

20M

budget

Electra impacts

Operational Objective Alignment

ELECTRA directly contributes to Process4Planet’s objective of developing new electrified processes and promoting energy efficiency, aligned with the broader goal of renewable energy utilization.

Carbon Capture Enhancement

By elevating CO2 concentration in flue gas to over 99%, ELECTRA simplifies and reduces the cost of carbon capture, supporting the development of efficient CO/CO2 capture and purification technologies.

FOAK Plant Advancement

Through industrial pilots, ELECTRA advances towards first-of-a-kind (FOAK) plants, driving innovation and derisking investment in electrified processes.

Key Exploitable Results (KER)

- Plasma heated rotary kiln for calcination and clinkering

- High-enthalpy plasma torch for oxidising conditions

- …

News and Events

21.11.2025

ICREC 2025 – 10th International Conference on Renewable Energy and Conservation

- date_range21-23 Novembre 2025

- pin_dropFlorence, Italy

21.11.2025

Radiation measurements at SINTEF’s plasma torch test chamber

19.11.2025