The project

The critical challenge addressed by ELECTRA is how to provide the heat to the processes that require high temperatures. Moreover, this must be achieved without compromising product quality and allowing flexibility in the power input. The processes in the cement, lime, and pulp have many aspects in common, but also differences in processing temperatures, raw material properties and product quality requirements.

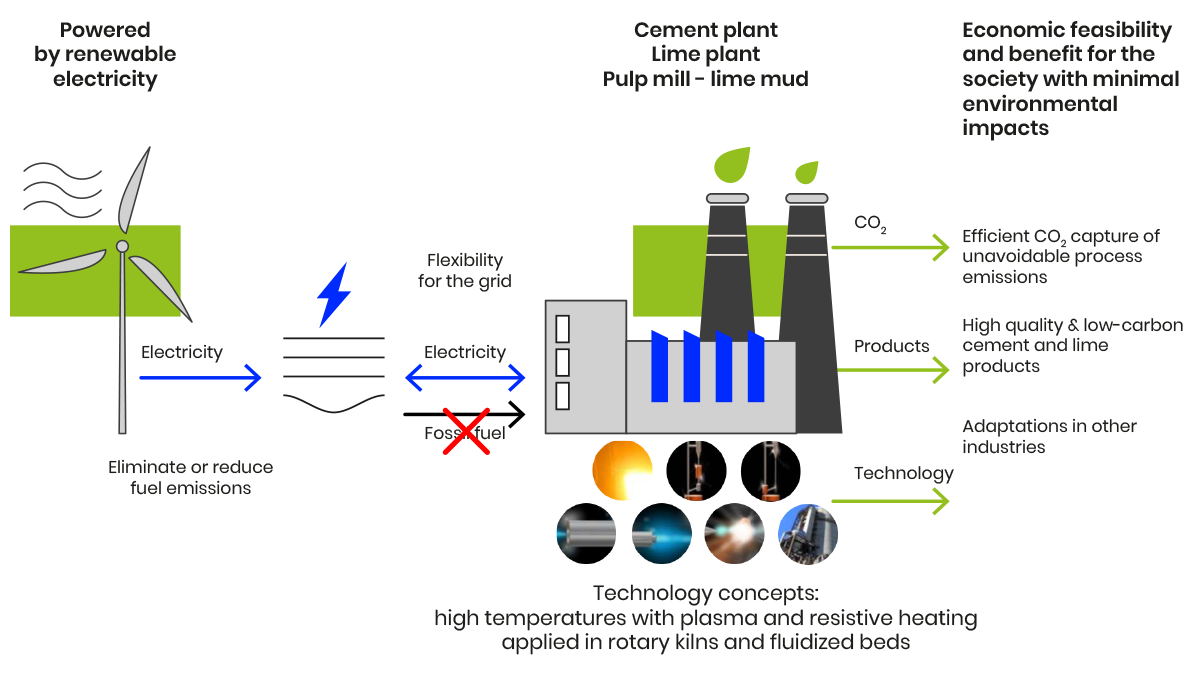

In ELECTRA, the hard-to-abate carbon dioxide emissions of the process industries are tackled with flexible electrification and CO2 capture. New electrified manufacturing technologies for cement, lime, and pulp industries will be developed, to drastically reduce the greenhouse gas emissions in the EU, by

- substituting fossil fuels with renewable electrical energy,

- enabling the efficient capture and use or removal of an undiluted CO2 stream from the decomposition of the raw material, calcium carbonate, and

- flexible power loads enabling a higher share of renewable electricity production in the electricity grid.

In ELECTRA, we solve these main challenges with several technology concepts, where the main components are plasma heating, resistive heating, rotary kiln, and fluidised bed technologies. We create the best technology concept for each industry and use case as a combination of these key elements. Even though the industries covered in ELECTRA, cement, lime and pulp, utilise similar high temperature processes, there are differences in material behaviour, process conditions, and product quality demands, for example. Thus, several technology concepts are developed in ELECTRA.

The approach in ELECTRA is illustrated below in Figure: